The Ultimate Guide to Picking the Right Bulk Containers for Your Service Requirements

Choosing the appropriate mass containers is vital for any kind of organization that relies upon efficient logistics. Various sorts of containers exist, each made for details materials and applications. Variables such as size, product compatibility, and governing requirements play a considerable function in this decision-making process. Comprehending these components can result in improved operational efficiency. Many organizations ignore essential aspects that might enhance their total performance and sustainability. What are these factors to consider?

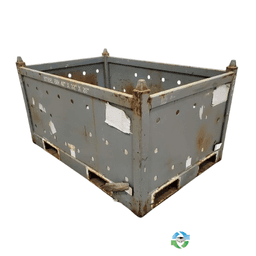

Understanding Various Types of Bulk Containers

Bulk containers act as important tools for businesses looking for efficient storage and transportation services. These containers can be found in various types, each designed to meet details operational requirements. One usual type is the intermediate mass container (IBC), which is ideal for granulated and fluid products, supplying an equilibrium of capability and ability to move. One more preferred choice is the mass bag, or FIBC, suitable for completely dry, flowable products. These versatile containers are lightweight and can be quickly carried and saved. For heavier materials, stiff mass containers are commonly used, offering toughness and stability for safe handling. Additionally, there are customized containers tailored for unsafe products, making sure conformity with security regulations. Comprehending the distinctive attributes of these bulk container types allows businesses to make enlightened decisions that optimize logistics and minimize prices. By picking the best container, firms can boost their functional efficiency and improve their supply chain processes.

Secret Material Considerations for Bulk Containers

When picking bulk containers, it is important to ponder the materials made use of in their building. Factors such as chemical, sturdiness, and strength compatibility play an essential duty in ensuring the containers fulfill particular operational requirements. Furthermore, weight and transportability concerns can impact both effectiveness and transport logistics.

Material Toughness and Stamina

Sturdiness and strength are important consider picking products for mass containers, as they straight affect the container's capability to withstand various ecological conditions and taking care of processes. Products such as high-density polyethylene (HDPE), polypropylene, and stainless steel are commonly preferred for their robust residential or commercial properties, offering resistance to abrasion, effect, and temperature level changes. The selection of material likewise impacts the overall life expectancy of the container; stronger materials normally cause much less frequent substitutes, bring about cost savings over time. Furthermore, the weight of the material can influence delivery prices and simplicity of handling. Organizations must consider their specific operational settings and the potential for damage to guarantee peak sturdiness and toughness in their bulk container option.

Chemical Compatibility Factors

Comprehending chemical compatibility is vital for choosing mass containers, as the materials used must resist the certain compounds they will hold. Numerous elements influence compatibility, consisting of the chemical nature of the components, temperature level, and duration of storage. Harsh chemicals might need containers made from stainless steel or specialized plastics that withstand destruction. Furthermore, responsive substances can create warm or gases, necessitating vented or pressure-rated containers. The option of container material, whether steel, polycarbonate, or polyethylene, should align with the chemical buildings of the kept materials to avoid breaches or leaks. Inevitably, a thorough evaluation of these compatibility elements guarantees risk-free handling and storage, securing both workers and the environment while keeping product stability.

Weight and Portability Concerns

Selecting mass containers includes not just examining chemical compatibility but likewise considering weight and portability. Businesses should evaluate the simplicity of handling and transport to optimize effectiveness. Lightweight products like high-density polyethylene (HDPE) or light weight aluminum can help with much easier motion and decrease delivery costs. Alternatively, heavier containers might offer boosted resilience however can impede flexibility, especially in settings calling for frequent relocation. Furthermore, the style of the container ought to permit convenient lifting and piling, ensuring ergonomic safety and security for employees. Firms should additionally consider the infrastructure offered for transport; for example, containers compatible with forklifts or pallet jacks can enhance procedures. Inevitably, the ideal balance between weight and mobility straight influences functional efficiency and price efficiency.

Sizing Your Mass Containers for Optimal Efficiency

When sizing mass containers, companies have to thoroughly evaluate the dimensions called for to fit their details products. In addition, weight capability is a vital variable that influences effectiveness and safety throughout transportation and storage space. Efficient sizing not only maximizes room yet likewise enhances operational process.

Figuring Out Container Dimensions

Choosing the appropriate measurements for bulk containers is important for taking full advantage of efficiency in storage space and transport. Services have to evaluate their particular requirements, thinking about elements such as offered space, the nature of the products being saved, and the methods of transport made use of. Exact dimensions ensure that containers fit preferably in lorries and storehouses, lessening lost area and lowering dealing with time. Criterion sizes can use benefit, however customized measurements could be essential for distinct demands or to fit certain items. In addition, it is very important to examine stacking capacities and ease of access, as these aspects influence general operational performance. Inevitably, the best measurements cause boosted organization and streamlined logistics, benefiting the general efficiency of the service.

Weight Capability Considerations

Understanding weight ability is important for organizations aiming to enhance their mass container performance. The weight capability of a container directly affects storage capacities, transportation logistics, and overall functional prices. Choosing containers with the ideal weight restrictions ensures that services can securely store and carry their items without risking damages or compliance concerns. Overloading containers can result in architectural failings, while underutilizing capacity outcomes in wasted sources. When selecting containers, it is vital for companies to assess their item weights and consider any type of regulatory needs. Furthermore, aspects such as the type of product, intended usage, and ecological conditions must additionally affect weight ability decisions. By assessing these aspects, organizations can boost effectiveness and ensure a structured supply chain.

Regulative Conformity and Security Standards

Regulative compliance and safety and security criteria play an important function in the option of mass containers for services. Organizations should ensure that their containers satisfy numerous policies set by regional, nationwide, and worldwide authorities. These standards usually relate to material safety and security, structural stability, and appropriate labeling, which aid stop accidents and guarantee the safe transportation of products.

Additionally, adherence to industry-specific standards, such as those from the Fda (FDA) or the Occupational Safety and Health And Wellness Administration (OSHA), is crucial for firms dealing with unsafe products or foodstuff. Non-compliance can lead to fines, lawful concerns, or damage to a company's online reputation.

Services ought to likewise take into consideration the container's compatibility with the materials being stored or moved to prevent contamination or chemical responses (used plastic containers). To summarize, comprehending and executing governing compliance and security criteria is important for the liable and reliable use mass containers

Sustainability Alternatives for Eco-Friendly Mass Containers

Companies are additionally discovering options made from recycled products, which not just save sources but additionally support the reusing industry. Developments in design permit for lighter containers that call for much less energy to transportation, better improving sustainability. By incorporating these eco-friendly bulk container choices, businesses can show their dedication to ecological stewardship while fulfilling consumer need for sustainable practices. This change not only assists the earth however can also enhance brand name credibility and customer commitment.

Cost-Effectiveness and Budgeting for Mass Containers

While many companies concentrate on sustainability, cost-effectiveness stays an essential element when choosing mass containers. Organizations needs to analyze the initial acquisition price, along with lasting functional costs, to assure financial stability. Factors such as maintenance, reusability, and toughness play a considerable role in identifying total expenditures.

Buying top notch containers might yield higher in advance prices but can cause cost savings via reduced replacement rates and reduced waste. Furthermore, companies must think about transportation expenses and storage efficiency, as these can affect the overall spending plan.

Regularly Asked Concerns

Just how Do I Determine the Right Container for Hazardous Products?

To establish the right container for dangerous products, one need to evaluate compatibility with the material, consider the container's product, look for regulatory conformity, and evaluate capacity and safety and security features to ensure appropriate handling and storage.

Can Mass Containers Be Customized for Certain Products?

Yes, bulk containers can be tailored for certain products. used plastic containers. Numerous functions, such as material, layout, and dimension, can be tailored to satisfy distinct requirements, making sure ideal security and effectiveness for moving and saving various products

What Is the Average Life Expectancy of Different Mass Container Kind?

The typical life expectancy of mass container kinds differs; plastic containers last 5-10 years, steel containers 10-20 years, and wooden containers generally last 3-7 years, depending upon use, maintenance, and environmental problems.

Exactly how Should I Tidy and Maintain Mass Containers?

To clean up and maintain bulk containers, one must consistently inspect for damage, eliminate residue, laundry with ideal cleaning agents, wash thoroughly, and warranty correct drying out prior to storage. Adhering to manufacturer guidelines enhances longevity and safety throughout use.

Are There Rental Options for Mass Containers Available?

Yes, numerous companies use rental choices for bulk containers, giving flexibility for companies. These rentals can suit different requirements, enabling firms to handle inventory efficiently without the commitment of acquiring containers outright.

Toughness and toughness are critical factors in picking materials for mass containers, as they directly influence the container's ability to stand up to numerous ecological problems and dealing with processes. Understanding chemical compatibility is important for choosing mass containers, as the materials utilized have to resist the certain materials they will hold. Comprehending weight ability is crucial for companies intending to enhance their mass container efficiency. Regulatory conformity and safety and security requirements play a necessary role in the selection of bulk containers for organizations. While numerous companies concentrate on sustainability, cost-effectiveness remains a crucial factor when selecting mass containers.